|

|

|

|

|

|

|

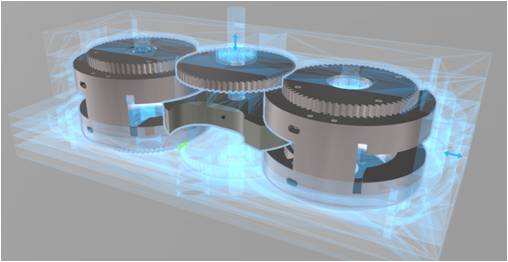

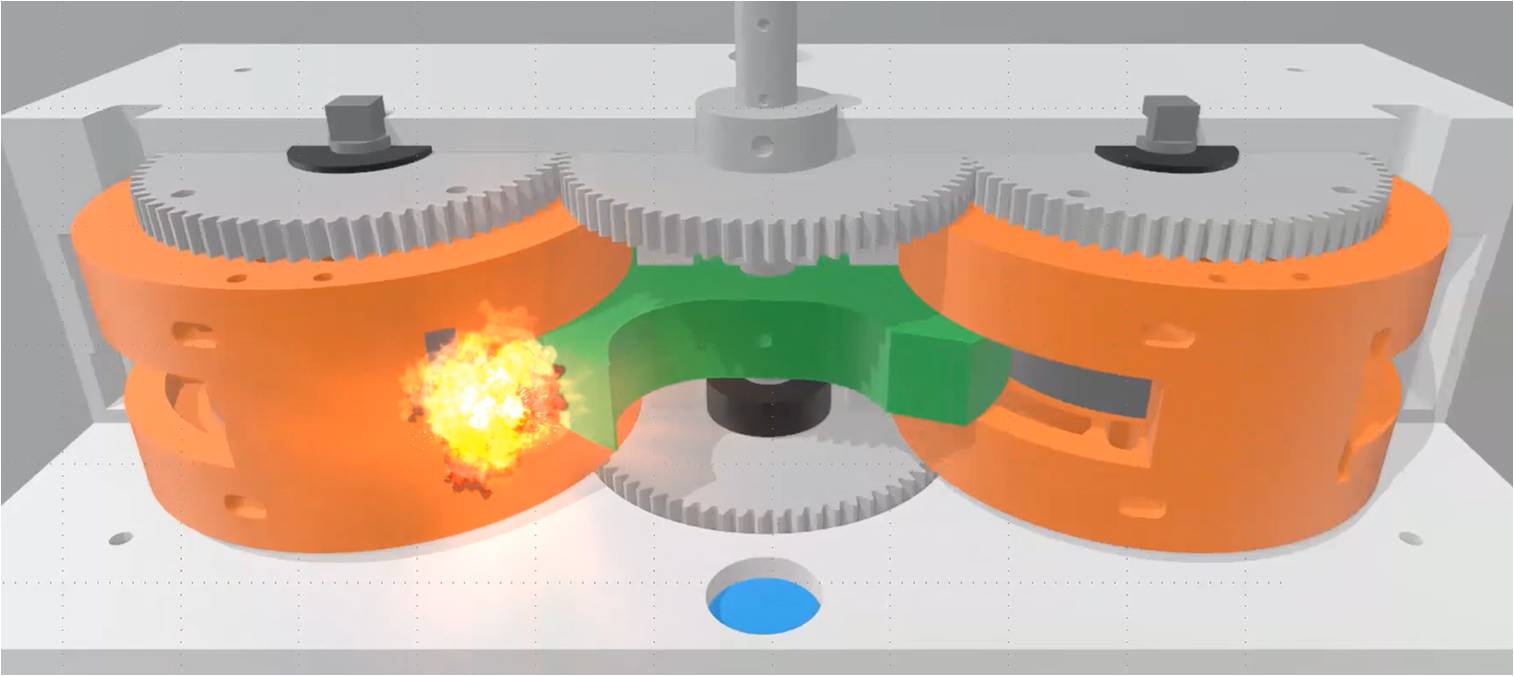

The continuous motion engine is being developed to improve energy efficiency and reduce pollution

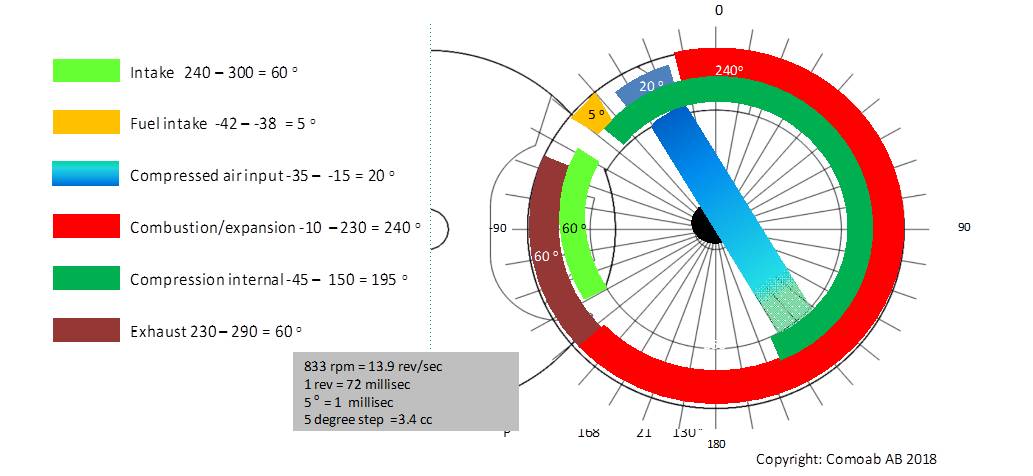

Key benefits over existing technology is having no reciprocating parts, running oil free, a long expansion cycle with higher efficiency. It is ideal option for the future of using hydrogen for combustion as it does not have an pre-ignition or engine knock problem.

The technology is patented in the US, patent number US10094218B1.

A first prototype has been developed and test results are used to design a commercial viable version

.

Change the world of energy production to reduce global warming

Goal is to provide an engine with reduced fuel consumption, reduced exhaust pollutants and a reduced cost of manufacturing.

Current reciprocating piston engines have a very low energy efficiency.

The engine is ideally suited for hybrid usage, loading the battery while running at an optimal speed for efficiency and reduced emissions. It can support a faster transition to electric vehicles at a lower cost for consumers and for the environment

Production of large heavy batteries for electric vehicles creates an increase of CO2 on the short term. Using hybrids this can be avoided.

The design having no reciprocating parts, provides an energy efficiency improvement as compared with current piston engines.

Lubricant oil-free operation and a long burn cycle reduces pollution.

Lean operation and wide range of renewable fuels reduces environmental impact.

The new design is based on a continuous motion revolving piston, without loss of energy due reciprocating parts

Many improvements on the piston engine have been proposed of which the Wankel engine has been the only one to be actually used in production cars

The piston engine has energy losses from reciprocating parts and requires oil lubrication

The Wankel engine does not have reciprocating parts but burns even more oil and fuel

The new design disrupts the reciprocating engine model and provides new opportunities for improvements

Clean tech

New design enables energy reduction of more than 20%

Increased output to weight ratio and engine size provides new implementation opportunities

New materials and manufacturing overcomes a 100 year old stagnation in development

Reduced components and complexity reduces costs

A 'no knock' engine, allows a range of fuels including hydrogen

Self starting, self cooling and oil free operation reduces total costs further

Everywhere

From home bio-gas fueled electricity generator to massive ship engines

Stationary, sea, land and air applications

Scalable to any size

Ideally used as hybrid loading EV-car batteries, running on renewable fuels

R&D for continuous innovation

Continuous motion, aimed at continuous improvement

R&D to support implementation

Research partnerships to build and share results

Development support for early adopters

Designed to demand

Free licenses for R&D and prototype testing

Commercial licenses supporting first adopters

Licensing fees used to support R&D partners

Specific to application area, supporting clean tech applications

Investing

Real product and patent driven licensing income returns

Initial investment directly used in R&D

20 year patent payback horizon & clean tech benefits